You are here:Home > NEWS > Company news

It is also the annual IPC International Welding Competition. The 2017 competition will be divided into three divisions: East China, North China and Southwest China. The China Finals will be held in Chengdu. The winners of the division will participate in the China Championship in Chengdu in July. The winners of China will have the opportunity to participate in the IPC Hand Soldering World Championships held in Munich, Germany in November! By then, they will represent China and hand soldering from Korea, Malaysia, Indonesia, India, Europe, USA, Thailand, Vietnam and other countries. The top players compete on the same stage, and they are famous at home and abroad!

The IPC International Welding Competition has been successfully held for eight consecutive years. The IPC manual welding competition has long been well-known in the international electronic assembly industry. It has been highly sought after by highly-feasible electronic assembly companies and employees, and the competition level has been improved year by year. This year's competition board will continue to increase the difficulty of operation to better test and select the player's operating level, welding skills, theoretical basis and adaptability.

The content of the 2017 competition requires the player to complete the assembly and welding of a well-functioning PCBA within 40 minutes. The evaluation criteria are still IPC-A-610F version "Reliability of Electronic Components" and IPC J-STD-001F Edition "Welding" Electrical and electronic components require a three-level product specification for the highest reliability requirements. The referee is an expert from all over the country who has the above two standard CIT certificates and has many years of experience in assembling process management. This year, there are more stringent screening requirements for the contestants. Each company has a maximum of two entries in the entire competition area.

This year will be held in the following three divisions of high-reliability electronics manufacturing:

East China Division - Suzhou Ÿ May 17-19 Ÿ East China Circuit Board and Surface Mount Exhibition

North China Division - Beijing, June 19-21, Beijing Defense Information Technology and Technology Exhibition

Southwest Division - Chengdu, July 13-14, China (Chengdu) Electronics Show

China Finals - Chengdu, July 15th, China (Chengdu) Electronics Show

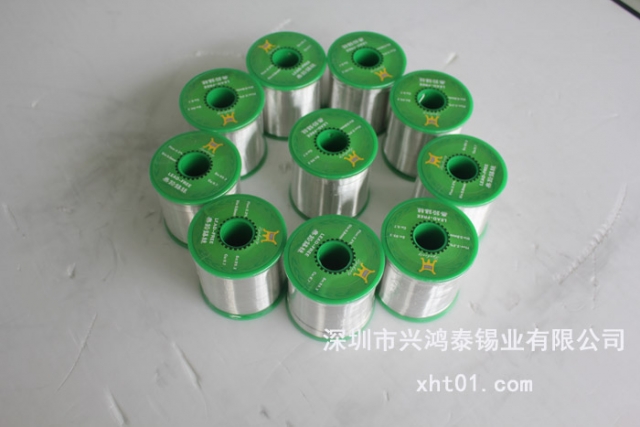

The 2017 IPC China Handmade Welding Competition will be sponsored by JBC, Cricket, and WELLER with a soldering iron. The players will draw lots to determine the soldering iron used in the competition; Intervos sponsors the cleaning agent, and Xinghongtai provides solder wire and flux sponsorship. The Anson Amber circuit provides support for sponsorship.

Xinghongtai solder wire Sn99.3Cu0.7 is made of high-purity tin raw material of Yunnan tin mine, which is refined by special process. The product rosin core is made of high-quality pure white transparent hydrogenated rosin with self-developed organic acid activity. The agent is made of vacuum sealed container, the process is special and reliable, and has the industry leading level; according to the activity of the rosin core, it can be divided into R type (low activity), RMA type (medium activity), RA type (high activity) Three types, widely used in the military industry, precision electronic equipment, high-end electronic products, home appliances, automotive electronics, precision medical equipment and other products of solder solder; after the preparation of organic acid active agents, the development of special tin wire products It can also be applied to soldering of lighting, jewelry, metal products, power materials, USB materials, wire materials and other products.

Xinghongtai solder wire not only has the characteristics of fast soldering speed, less spatter, bright solder joints, low smoke, high insulation resistance, but also has the dual functions of fast soldering for copper and nickel materials, and slightly adjusts the production process. After that, the automatic soldering special tin wire product developed can be applied to the soldering operation of the automatic soldering machine, which enhances the versatility of the soldering wire, adds some convenience to the customer's production process, and is suitable for the rapid development of the modern electronic industry and the welding process. Demand, after years of practical use, this product has been recognized by well-known companies, customers can use with confidence.

Copyright © 2005 - 2013 Shenzhen Xinghongtai Tin Industry Co., Ltd. 粤ICP备15029771号-1

Technical support: GRWY Site Map Disclaimer

Consultation

Consultation

+86 13530302266

+86 13530302266